Products

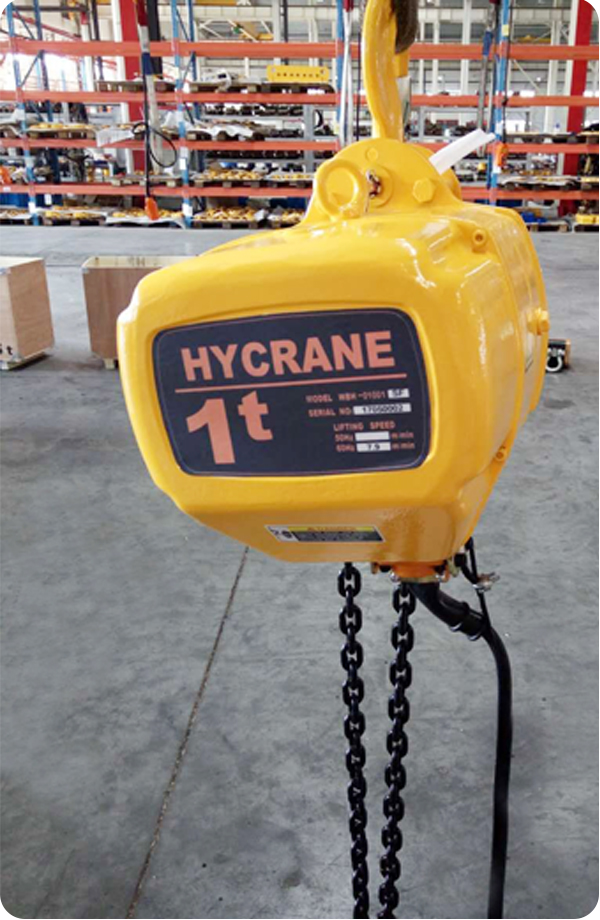

Cheap electric chain hoist with strong hook

Description

Electric chain hoists, also known as electric chain motors or simply

chain hoists, are a type of lifting equipment commonly used in a

wide range of industrial applications. Their main components include

an electric motor, a gearbox, a chain, and a lifting hook or other

attachments. The unique feature of this type of hoist is the use of

a chain, which is looped around the motor's output shaft and

connected to the lifting hook.

The primary structural characteristics of electric chain hoists

contribute to their reliability, simplicity, and ease of use. The

chain drive system, for example, provides smooth and precise lifting

action, while also allowing for accurate and consistent load

control. The gearbox, which converts the motor's high-speed turning

torque to a

slower but more powerful torque, ensures that the load is lifted

efficiently and safely. Additionally, the use of an electric motor

eliminates the need for a cumbersome and maintenance-intensive

external power source.

Electric chain hoists offer several advantages in industrial

settings. Their compact size and ability to be easily maneuvered

make them well-suited for working in confined spaces or in areas

with limited access. The chain drive system also allows for smooth

and controlled lifting, which is crucial when handling delicate or

fragile loads. Furthermore, electric chain hoists are highly

efficient, providing excellent power-to-weight ratio, making them

suitable for lifting heavy loads over short distances.

Electric chain hoists play an essential role in various industrial

applications, including manufacturing, construction, and material

handling. They are frequently used to lift and move heavy loads,

such as machinery, inventory, and construction materials, as well as

for general lifting tasks. Their combination of reliability,

efficiency, and ease of use has made electric chain hoists a crucial

component in industrial lifting operations.

Product Features

· Automatic double-pawl braking system

· Gear: by adopting Japanese technology,they are

innovated symmetrical arrayed high speed synchronous

gears, and are made from international standard gear

steel.Compared with common gears ,they are more wearable

and steadier, and more laborsaving.

· Got certificate of CE

· Chain: adopts high strength chain and high precision

welding technology,meet ISO30771984 international

standard;fits for gusty overload work conditions;takes

your hands a better feeling multi-angle operation.

· Have certificate of ISO9001

· Hook: made of high-class alloy steel,it has high

strength and high security; by using new design,weight

will never escape.

· Components:main components are all made of high-class

alloy steel,with high precision and security.

· Framework: slight design and more beautiful; with less

weight and smaller work area.

· Capacity from 0.5t to 50t

· Plastic Plating: by adopting advanced plastic plating

technology inside and outside,it looks like a new one

after years of operation.

· Encloser: made of high-classed steel,more firmly and

dexterous.

Product Characteristics

| Parameters of Electric Chain Hoist | |||||||

|---|---|---|---|---|---|---|---|

| Item | Electric Chain Hoist | ||||||

| Capacity | 1-16t | ||||||

| Lifting height | 6-30m | ||||||

| Application | Workshop | ||||||

| Usage | Construction Hoist | ||||||

| Sling Type | Chain | ||||||

| Voltage | 380V/48V AC | ||||||

Product Details

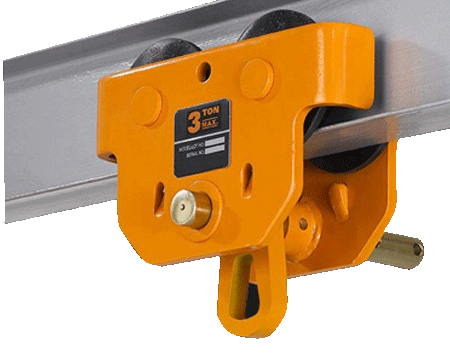

Electric Hoist Trolley

Equipped with electric hoist, it can form a bridge-type single-beam and cantilever crane, which is more labor-saving and convenient.

Manual Hoist Trolley

The roller shaft is equipped with roller bearings, which has high walking efficiency and small pushing and pulling forces

Motor

Using pure copper motor, it has high power,

fast heat dissipation and longer service

life

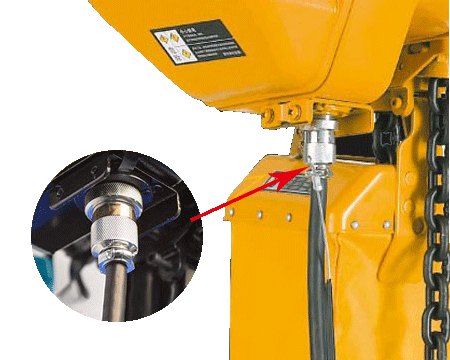

Aviation plug

Military quality, meticulous workmanship

Chain

Super heat-treated manganese steel chain

Hook

Manganese steel hook, hot forged, not easy to break

Fine Workmanship

Complete

Models

Adequate

Nventory

Prompt

Delivery

Support

Customization

After-sales

Consultation

Attentive

Service

HYCrane VS Others

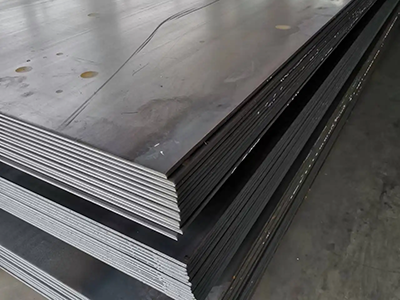

Our Material

1. The raw material

procurement process is strict and

has been inspected by quality inspectors.

2. The materials used are all steel products from

major steel mills, and the quality is

guaranteed.

3. Strictly code into inventory.

1. Cut corners, originally used 8mm steel

plate,but used 6mm for customers.

2. As shown in the picture, old equipment is often

used for refurbishment.

3. Procurement of non-standard steel from small

manufacturers, product quality is unstable.

Other Brands

Our Motor

1. Motor reducer and brake

are three-in-one

structure

2. Low noise, stable operation and low maintenance

cost.

3. The built-in anti-drop chain can prevent

the bolts from being loosened, and avoid the

harm to the human body caused by the accidental fall

of the motor.

1.Old-style motors: It is noisy, easy to wear, short

service life, and high maintenance cost.

2. The price is low and the quality is very poor.

Other Brands

Our Wheels

All wheels are heat-treated and modulated, and the surface is coated with anti-rust oil to increase the aesthetics.

1. Do not use splash fire modulation, easy to

rust.

2. Poor bearing capacity and short service life.

3. Low price.

Other Brands

Our Controller

1. Our inverters make the crane run more stable

and safe, and make the maintenance of the more

intelligent and easy.

2. The self-adjusting function of inverter

allows motor to self-adjust its power output

according to the load of the hoisted object at any

time, thereby saving the factory costs.

The control method of the ordinary contactor allows the crane to reach the maximum power after it is started, which not only causes the whole structure of the crane to shake to a certain degree at the moment of starting, but also slowly loses the service life of the motor.

Other Brands

Transport

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.