Products

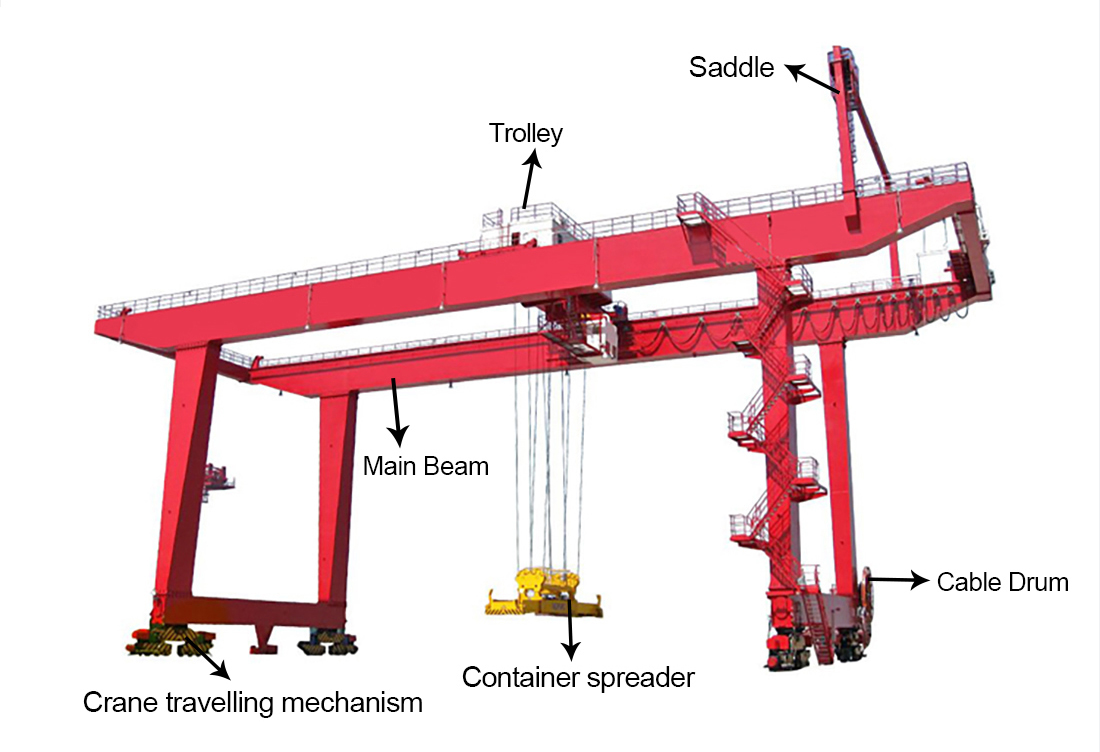

CE ISO rail mounted 41 Ton Mobile Container Lifting Gantry Crane

Description

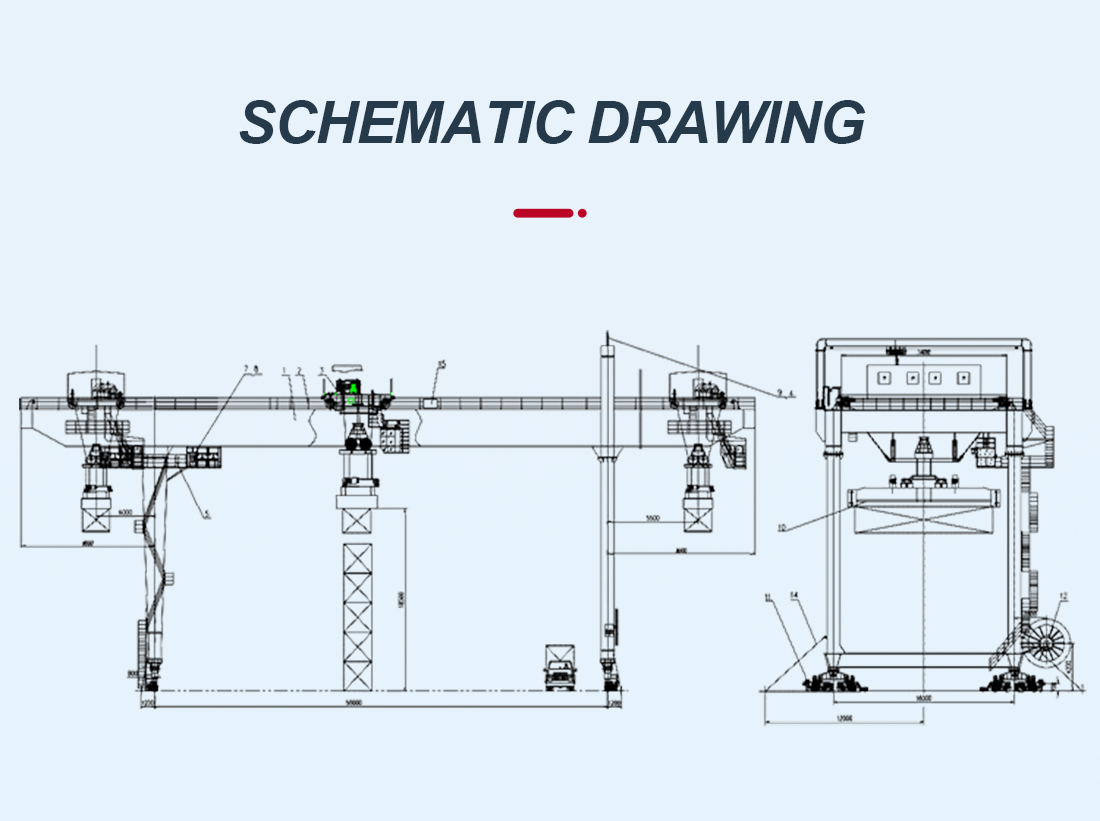

Rail mounted container gantry crane is appropriate for handling, loading and unloading ISO container and railway wide container in container yard or transfer station such as port, wharf, railway and logistics. Supported by multiple steel wheels and powered by electricity, it consists of gantry mechanism, trolley assembly, gantry frame, power system and special container spreader.

The design, manufacture and inspection comply with Chinese standard and international standards such as FEM, DIN, IEC,AWS and etc. RMG has the characteristics of multiple function, high efficiency, stability, reliability, wide range of operation, easy operation and maintenance.

It is also completed with safety indication and overload protection device to provide maximum safety for operators and equipment. The electric drive adopts fully digital AC variable frequency and PLC speed control technology with flexible control and high accuracy. Standard bought-in components from well-known brands at home and abroad ensure overall quality.

It is also completed with safety indication and overload protection device to provide maximum safety for operators and equipment. The electric drive adopts fully digital AC variable frequency and PLC speed control technology with flexible control and high accuracy. Standard bought-in components from well-known brands at home and abroad ensure overall quality.

Technical Features

1.Standard two-way flexible resistance anti-swing system, multiple function frequency control anti-swing inching system and electronic anti-swing system as option, perfect anti-swing effects, easy maintenance.

2.CMS intelligent service management system, real-time monitoring of running status.

3.Vector frequency conversion, electric energy feedback, torque balance control, energy saving and environmental protection, convenience and efficiency.

4.Automatic fault detection and real-time data display, safety and reliability.

5.Multiple operation mode---manual, semi-automatic and automatic remote operation, complete with advanced technology and stable performance.

6.Applied core technologies such as automatic running positioning, flexible landing on containers, trajectory intelligent control,intelligent tilting anti-snag safety protection and etc.

7.A variety of safety measures, including strong wind alarm, safety dynamic scanning

3.Vector frequency conversion, electric energy feedback, torque balance control, energy saving and environmental protection, convenience and efficiency.

4.Automatic fault detection and real-time data display, safety and reliability.

5.Multiple operation mode---manual, semi-automatic and automatic remote operation, complete with advanced technology and stable performance.

6.Applied core technologies such as automatic running positioning, flexible landing on containers, trajectory intelligent control,intelligent tilting anti-snag safety protection and etc.

7.A variety of safety measures, including strong wind alarm, safety dynamic scanning

Product Details

Main Beam

1.With strong box type andstandard camber

2.There will have reinforcementplate inside themain girder.

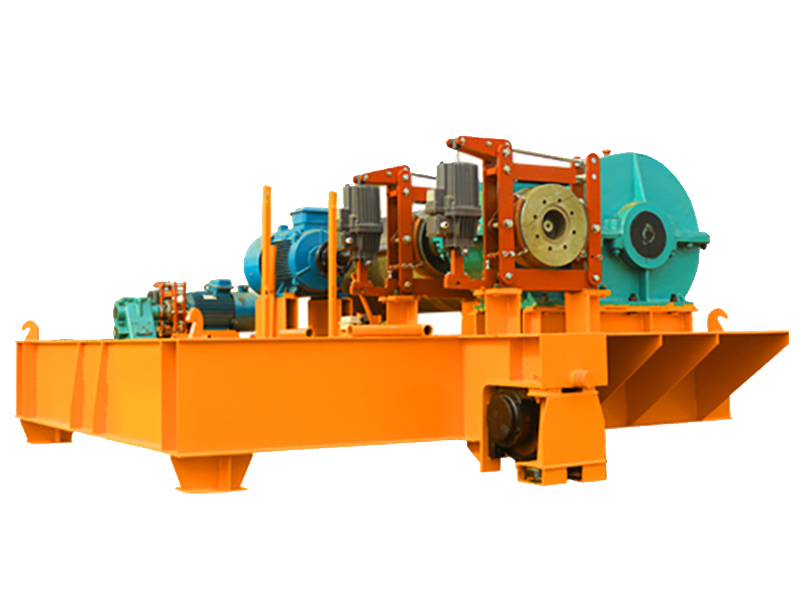

Cable Drum

1.The altitude does not exceed2000 meters.

2.The protection class ofthe collector box is lP54.

Crane Trolley

1. High working duty hoist mechanism.

2. Working duty: A6-A8.

3. Capacity: 40.5-7Ot.

Container Spreader

Reasonable structure, good versatility , strong carryingcapacity, and can be processed and customized

Crane Cabin

1.Close and open type.

2.Air-conditioning provided.

3.Interlocked circuit breakerprovided.

Technical Parameters

Technical Parameters

|

Lifting weight (t)

|

10

|

16

|

20/10

|

32/10

|

36/16

|

50/10

|

||

|

Span (m)

|

18~35

|

18~30

|

18~35

|

22

|

26

|

22~35

|

35

|

|

|

Lifting height (m)

|

Main hook

|

11.5

|

10.5,12

|

10.5

|

11.5

|

11.5

|

12

|

|

|

Auxiliary hook

|

11

|

12

|

12

|

13

|

||||

|

Speed (m/min)

|

Main hook

|

8.5

|

7.9

|

7.2

|

7.5

|

7.8

|

6

|

|

|

Auxiliary hook

|

10.4

|

10.4

|

10.5

|

10.4

|

||||

|

Trolley travel

|

43.8

|

44.5

|

44.5

|

41.9

|

41.9

|

38.13

|

||

|

Long travel

|

37.6,40

|

38,36

|

38,36

|

40

|

40,38

|

38

|

||

|

Duty classification

|

A5

|

|||||||

|

Power source

|

Three-phase AC. 127~480V 50/60Hz

|

|||||||

Write your message here and send it to us