Products

Reliable China Manufacturer Single Girder Gantry Crane with A Frame

Description

Single girder gantry cranes play a significant role in various

industries with their unique structure and functionality.

In the manufacturing industry, single girder gantry cranes are

widely used for lifting and moving heavy materials and equipment.

These cranes provide efficient handling solutions, especially in

areas where overhead cranes cannot be installed. They are commonly

used in the assembly lines of automobile and aerospace industries,

where they facilitate the transportation of heavy components and aid

in the production process.

In the construction industry, single girder gantry cranes are

essential for lifting heavy construction materials, such as steel

beams, concrete blocks, and machinery. Their mobility makes them

ideal for construction sites where the requirement for handling

heavy loads changes frequently. These cranes offer the advantage of

flexibility and adaptability, enabling workers to operate

efficiently in different project scenarios.

In the shipping and logistics industry, single girder gantry cranes

play a crucial role in loading and unloading cargo at ports or

warehouses. They are often used to handle containers, bulk goods,

and heavy equipment. The versatility of these cranes allows for

efficient loading and unloading operations, ensuring timely delivery

and minimizing downtime.

The structure of single girder gantry cranes is characterized by a

horizontal beam (the girder), supported by vertical legs on each

end. The single girder design provides stability and strength while

minimizing material and operational costs. The gantry frame can be

made of steel or aluminum, depending on the specific requirements of

the industry. The lifting mechanism typically includes a hoist or a

trolley, which travels along the girder, allowing for smooth and

precise movements.

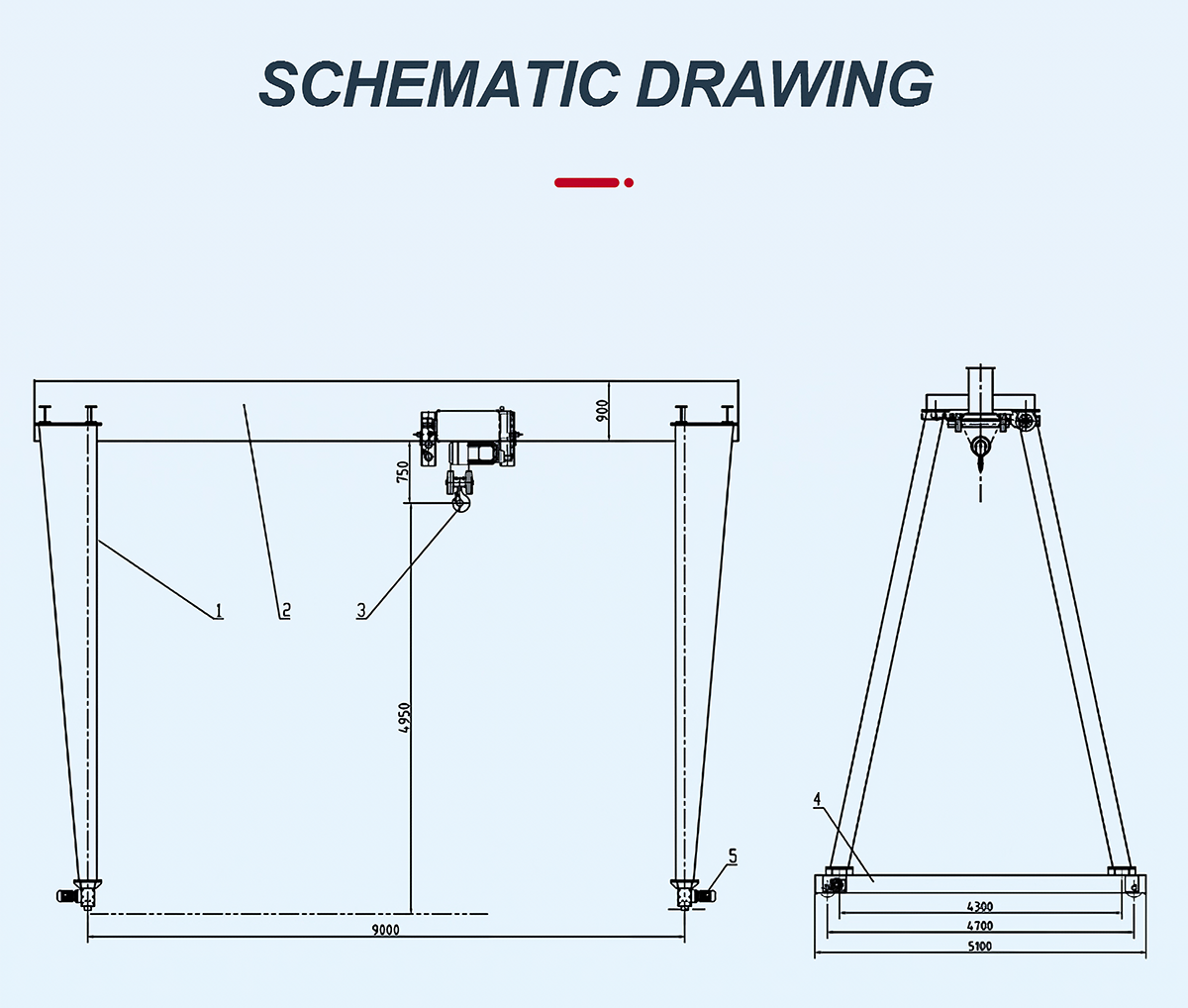

Schematic Drawing

Technical Parameters

| Parameters of Single Girder Gantry Crane | |||||||

|---|---|---|---|---|---|---|---|

| Item | Unit | Result | |||||

| Lifting capacity | ton | 3.2-32 | |||||

| Lifting height | m | 6 9 | |||||

| Span | m | 12-30m | |||||

| Working environment temperture | °C | -20~40 | |||||

| Travelling speed | m/min | 20 | |||||

| lifting speed | m/min | 8 0.8/8 7 0.7/7 3.5 3 | |||||

| travelling speed | m/min | 20 | |||||

| working system | A5 | ||||||

| power source | three-phase 380V 50HZ | ||||||

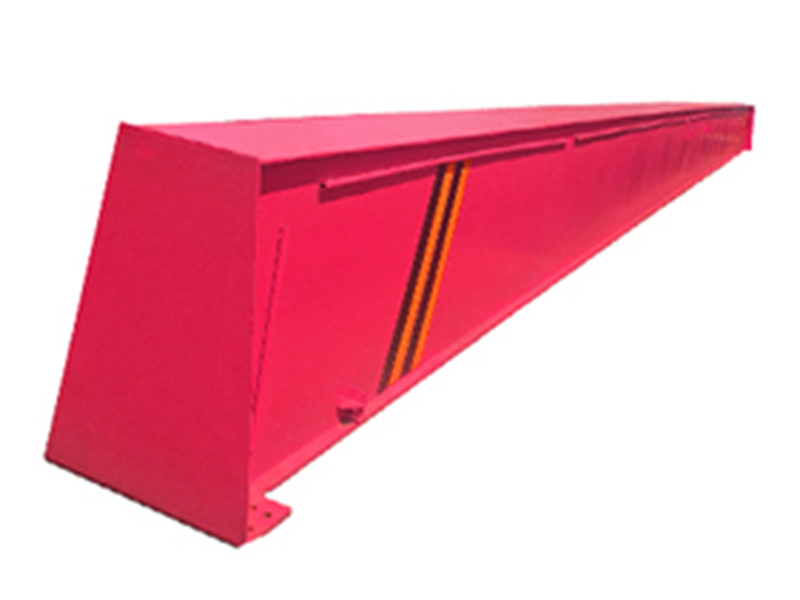

01

Main Beam

——

1.With strong box type andstandard camber

2.There will have reinforcementplate inside themain

girder

02

Crane Leg

——

1.Supporting effect

2.Ensure safety and stability

3.lmprove the lifting characteristics

03

Hoist

——

1.Pendent & remote control

2.Capacity:3.2-32t

3.Height: max 100m

04

Ground Beam

——

1.Supporting effect

2.Ensure safety and stability

3.Improve the lifting characteristics

05

Crane Cabin

——

1.Close and open type.

2.Air-conditioning provided.

3.Interlocked circuit breakerprovided.

06

Crane Hook

——

1.Pulley Diameter:125/0160/0209/O304

2.Material:Hook 35CrMo

3.Tonnage:3.2-32t

Fine Workmanship

Low

Noise

Fine

Workmanship

Spot

Wholesale

Excellent

Material

Quality

Assurance

After-Sale

Service

01

Raw Material

——

GB/T700 Q235B and Q355B

Carbon Strctural Steel, best quality steel plate from

China Top-Class mills with Diestamps inlude heat

treatment number and bathch number, it can be tracked.

02

Welding

——

American welding Society, all important welds are carried out in accordance with welding procedures strictly.After welding, a certain amount of NDT control is carried out.

03

Welding Joint

——

The appearance is uniform.The joints between the weld passes are smooth.All off the welding slags and splashes are cleared out. There are no faults such as cracks,pores,bruises etc.

04

Painting

——

Before painting metal surfaces are shot peening sa required, two coats of pimer before assembly,two coats of synthetic enamel after testing. Painting adhesion is accorded to the class I of GB/T 9286.

Transport

PACKING AND DELIVERY TIME

We have a complete production security system and experienced workers to ensure timely or early delivery.

RESEARCH ANDDEVELOPMENT

Professional power.

BRAND

Strength ofthe factory.

PRODUCTION

Years ofexperience.

CUSTOM

Spot isenough.

Asia

10-15days

Middle East

15-25days

Africa

30-40days

Europe

30-40days

America

30-35days

By National Station exporting standard plywood box,wooden palletor in 20ft & 40ft Container.Or as per your demands.